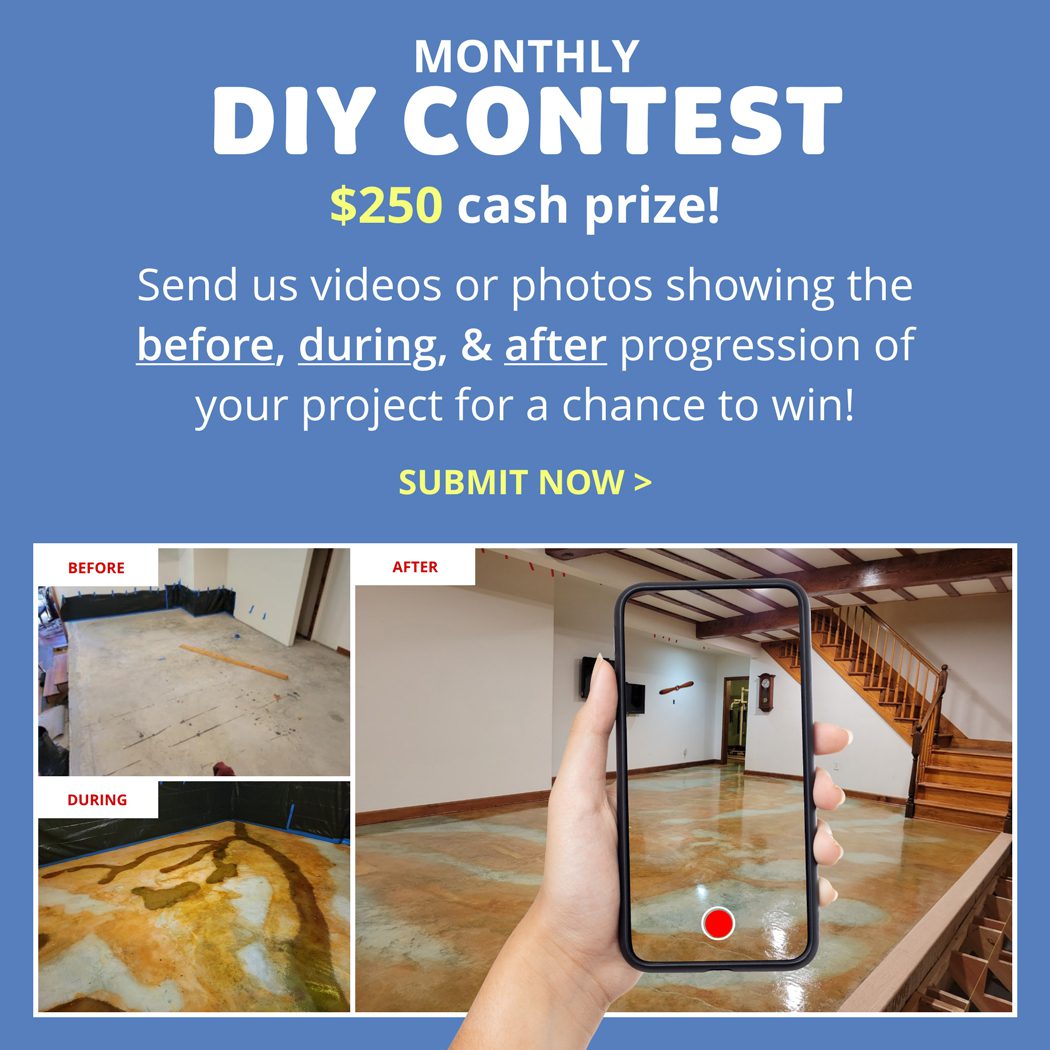

Step-by-Step Guide: Neutralizing Concrete Acid Stain for a Durable, Professional Finish

By Justin Richardson

Are you ready to dive into the world of concrete acid staining? It’s an exciting process that can transform your concrete floors into stunning works of art. But, hold on! You don’t want all your hard work to go to waste by not neutralizing the acid stain properly. Ensuring proper neutralization is crucial for sealer bonding and a durable, aesthetically pleasing finish. Without it, you might end up with a peeling, blotchy surface that just won’t do justice to your efforts. So, let’s make sure you get it right! And don’t forget, always wear spiked shoes while walking on un-neutralized acid stain to prevent visible footprints in the final product, ensuring a consistent and professional finish.

Before we start, remember to always wear spiked shoes while walking on un-neutralized acid stain to prevent visible footprints in the final product, ensuring a consistent and professional finish.

Here’s a step-by-step process to help you neutralize concrete acid stain effectively:

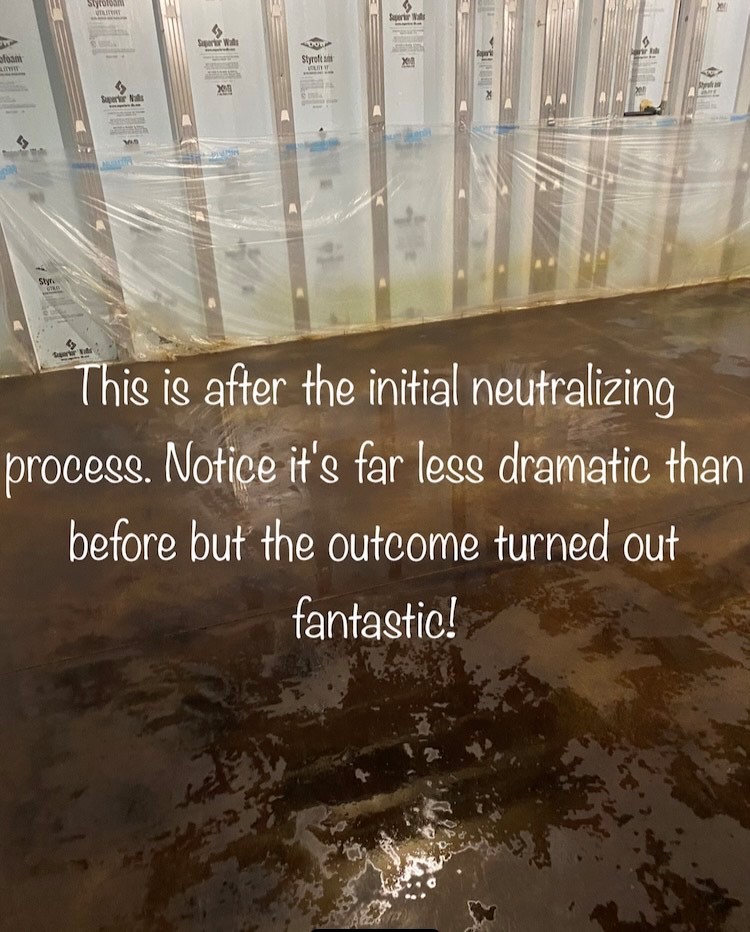

1. Start by saturating the stained concrete surface with a product like ProClean Neutralizer™. This helps neutralize the acid stain and prepares the surface for thorough cleaning.

2. Gently scrub the neutralizer into the concrete using a soft nylon bristle brush, taking care to wear your spiked shoes during this process. Let it sit for about 20 minutes to ensure proper neutralization.

3. After the acid stain is neutralized, reapply ProClean Neutralizer™ to the concrete surface as it also serves as a cleaner. Gently scrub it into the concrete with a soft nylon bristle brush.

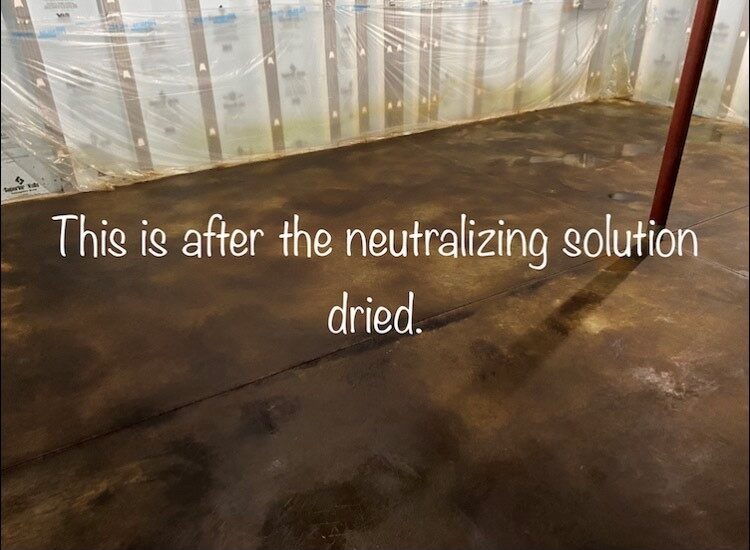

4. Continue scrubbing and rinsing with clean water until the rinse water is clear. A shop vac can be helpful in removing excess water during this process.

5. To make sure the surface is adequately cleaned, swipe your fingers across the rinsed and cleaned acid stained surface. If you don’t see any color or residue on your fingers, it’s time to let the surface dry completely before applying the sealer.

By following these steps, you’ll be able to neutralize concrete acid stain and ensure proper sealer adhesion for a long-lasting, vibrant finish. For more information on activation times and how long to leave acid stain on concrete, check out our blog titled ‘Activation Times For Concrete Acid Stains: How Long To Leave Acid Stain On Concrete.’ If you’re interested in a detailed step-by-step guide for a complete project with the images used in this blog, we invite you to read our blog post, ‘Make Concrete Floors Look Like Leather With Acid Stains.‘ Happy staining!”