DIY Guide: How to Stain Your Concrete Basement Floor – Tips, Tricks, and Expert Advice

Are you looking for a way to update your concrete basement floor? Staining your concrete floor is a great way to add color, character and beauty to your basement. In this blog, we’ll walk you through the process of staining your concrete basement floor. From preparing the surface to selecting the right stain, we’ll provide you with all the tips and tricks you need to achieve a professional-looking finish. Whether you’re a DIY enthusiast or a homeowner looking to make some changes, our guide on how to stain concrete basement floor will help you achieve the perfect finish for your space.

Step 1 – Check for Water Issues

Before staining your basement concrete floor, it is important to check for any water issues that may affect the project. Basements are prone to water issues such as drainage changes, foundation cracks, and heavy rains, which can cause moisture to leak into the basement or come up through the slab.

To ensure that you choose the right concrete sealer for your project, inspect your basement thoroughly for any leaks or moisture and address these issues before proceeding with the staining process.

Test the concrete humidity by sticking a sheet of plastic to the floor with duct tape and leaving it for at least 48 hours. If condensation is present under the plastic, choose a breathable sealer or a concrete cure and seal that allows water vapor to pass through the coating.

Step 2 – Evaluate Your Concrete

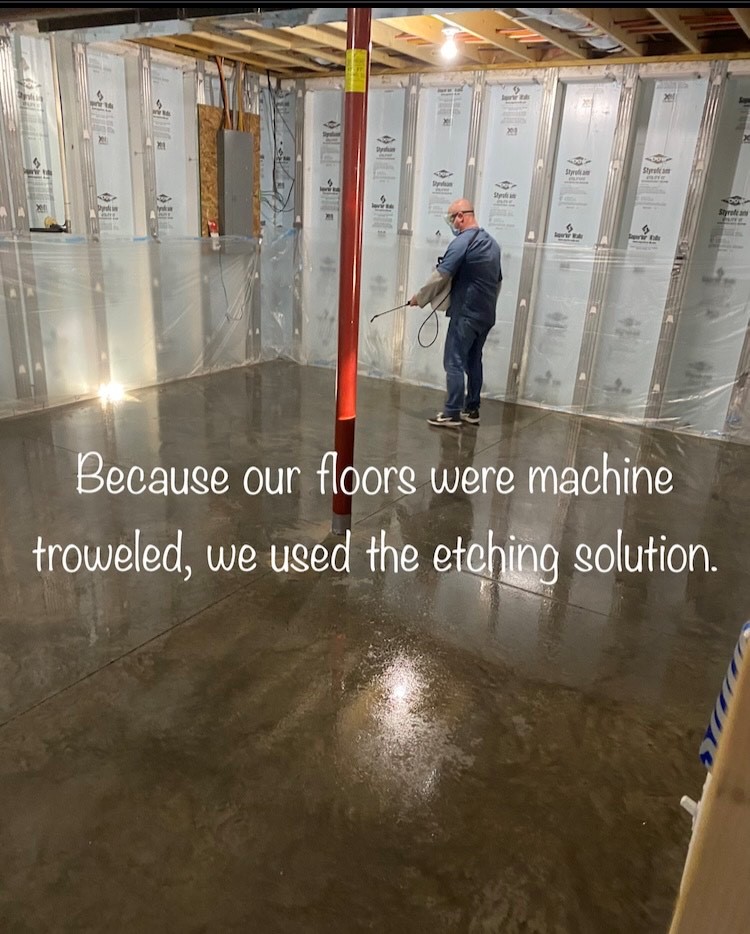

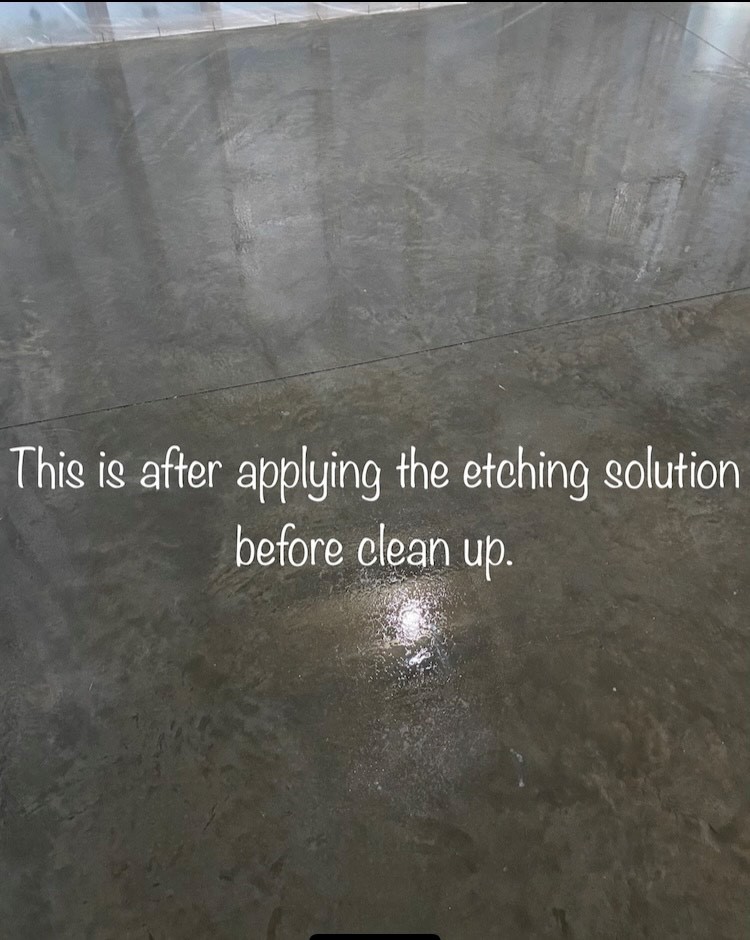

Evaluating your concrete is an important step in preparing to stain your basement floor. If the surface is smooth, it can be difficult to stain, so pre-treating the surface with a chemical or mechanical profiling product can help the stain take effect.

To determine if your concrete needs to be treated, pour some water on it and observe how it reacts. If the water beads up or absorbs poorly, the surface may be too smooth to stain and will need to be profiled.

One option is to use a product like CitrusEtch™ concrete etcher, which can be mixed with water and applied to the surface using a pump sprayer. After 15-20 minutes, wash off the etcher with clear water and test again to see if the water beads up. If the surface is excessively smooth, it may be necessary to apply a full-strength floor prep product.

Step 3 – Prepare Surface

Most basement floors usually have carpet or paint. All debris including glue, sealer, paint, and drywall mud must be completely removed before staining. Mastic Remover and Soy Gel Stripper are great low-odor products suitable for basement use.

Incorrect Surface Preparation

Correct Surface Preparation

Remember to clean the floor thoroughly of all cleanser residue using ProClean concrete cleaner and degreaser. Rinse it well and allow it to dry completely before proceeding with the staining process.

Remove any old paint or carpet glue and clean the floor thoroughly. If necessary, rent a concrete grinder to create a clean slate to work with.

Additionally, you may need to repair cracks with concrete patch and sand the surface for an even finish before staining.

Step 4 - Choose the Right Type of Concrete Stain

When it comes to staining a concrete basement floor, the best types of stains depend on the desired look and finish, as well as the condition of the concrete. The most popular types of stains for concrete basement floors are:

- Acid-based stains: They are the most popular choice for staining concrete floors. They penetrate the surface of the concrete and react chemically to create a unique, mottled look. They can be used to create a variety of colors and patterns, and are permanent and UV resistant.

- Water-based stains: They are another popular option for staining concrete floors. They are easy to apply and clean up, and they offer a wide range of colors. They don’t react chemically with the concrete, so the final color is more predictable. They also don’t emit strong odors like acid-based stains.

- Concrete dyes: They are similar to water-based stains in that they are easy to apply and clean up, and they offer a wide range of colors. Unlike acid and water-based stains, concrete dyes are not absorbed into the concrete, they are applied on the surface and penetrate into the pores of the concrete. They can be used to achieve a more consistent and controlled color than acid or water-based stains.

- Colored concrete sealers: Another option is the use of colored concrete sealers, they are a type of acrylic sealer that can be used to enhance the color of concrete surfaces and protect them from stains and water. They are available in a wide range of colors and can be used to achieve a subtle or bold color change.

Before applying a concrete stain to your basement floor, it’s essential to test the colors and sealer finish combinations to find the best one that works for your space. Our Concrete Stain Trial Kits allow you to experiment with up to three different stain colors and one sealer finish, allowing you to create a custom look for your basement floor.

Step 5 - Apply Concrete Stain

The following are brief descriptions of how to apply each type of stain on basement floors. For a more detailed guide with visual examples, check out our Stained Concrete Basement Floors – Transform Your Basement With Inspiration And Expert Tips gallery to help you see the finish of each type of stain and give you ideas.

Staining Basement Floor with EverStain Acid Stain

The application of EverStain acid stain on a concrete basement floor is a multi-step process that requires proper surface preparation, application of the stain, and proper sealant application to protect and enhance the final look. The steps are:

- Surface preparation: This includes cleaning the concrete surface, removing any existing coatings or sealers, and etching the surface with muriatic acid to open up the pores of the concrete for better absorption of the stain.

- Application of the stain: This involves applying the EverStain acid stain to the concrete surface using a pump-up sprayer. The stain should be allowed to react with the concrete surface for at least 4 hours for optimal results.

- Neutralizing and rinsing: Once the desired color has been achieved, the surface should be neutralized with a solution of baking soda and water to stop the acid reaction and neutralize the surface. The surface should then be rinsed with clean water to remove any remaining residue.

- Sealing: Once the surface has been cleaned, neutralized, and rinsed, it should be sealed with a concrete sealer to protect the surface and enhance the final look.

- Concrete floor wax application: After the sealer has dried completely, a concrete floor wax should be applied to the surface to provide an additional layer of protection and to prolong the sealer’s durability.

For a comprehensive and detailed guide on how to stain your concrete basement floor using acid stains, refer to our guide “Acid Staining Your Basement Floor: A Step-by-Step Guide.” It provides clear instructions and helpful tips to ensure a successful and professional-looking outcome.

Staining Basement Floor with ColorWave Water-Based Stain

The application of ColorWave Water-Based Stain on a concrete basement floor is a multi-step process that requires proper surface preparation, application of the stain, and proper sealant application to protect and enhance the final look. The steps are:

- Surface preparation: This includes cleaning the concrete surface, removing any existing coatings or sealers, and etching the surface with a concrete surface etcher for better absorption of the stain.

- Application of the stain: ColorWave Water-Based Stain is applied to the concrete surface using a pump-up sprayer. Spray the stain on the surface in slightly circular motions with irregular overlaps to achieve a more natural looking finish.

- Sealing: Once the surface has been cleaned and the stain has been applied, it should be sealed with a concrete sealer to protect the surface and enhance the final look.

- Concrete floor wax application: After the sealer has dried completely, a concrete floor wax should be applied to the surface to provide an additional layer of protection and to prolong the sealer’s durability.

For a comprehensive and detailed guide on how to stain your concrete basement floor using ColorWave Water-Based Stain, refer to our guide “Staining Your Basement Floor with ColorWave: A Step-by-Step Guide.” It provides clear instructions and helpful tips to ensure a successful and professional-looking outcome.

Staining Basement Floor with Vibrance Dye

The process of applying Vibrance Dye to a concrete basement floor is a multi-step process that involves proper surface preparation, mixing, and application of the dye, and proper sealant application to protect and enhance the final look. The steps are:

- Surface preparation: This includes cleaning the concrete surface, removing any existing coatings or sealers, and etching the surface with CitrusEtch to open up the pores of the concrete for better absorption of the dye.

- Mixing and application of the dye: This involves mixing the Vibrance dye powder with acetone, and applying it to the concrete surface using an acetone-grade sprayer. The dye should be worked on the surface in slightly circular motions with irregular overlaps. For deeper color, apply additional thin coats (maximum of four).

- Sealing: Once the desired color has been achieved, the surface should be sealed with a concrete sealer to protect the surface and enhance the final look.

- Concrete floor wax application: After the sealer has dried completely, a concrete floor wax should be applied to the surface to provide an additional layer of protection and to prolong the sealer’s durability.

CAUTION: When preparing the concrete dye mixture with acetone, it is important to use caution. Do not mix the dye and acetone in the sprayer using any type of electrical mixer. Acetone is highly flammable and using an electrical mixer could pose a fire risk. Instead, manually mix the dye and acetone using a stir stick or by shaking the container vigorously. As always, be sure to store and use acetone in a well-ventilated area and keep it away from heat, sparks, and open flames.

For a comprehensive and detailed guide on how to dye your concrete basement floor, refer to our guide “Concrete Dyeing Your Basement Floor: A Step-by-Step Guide.” It provides clear instructions and helpful tips to ensure a successful and professional-looking outcome.

Staining Basement Floor with AcquaTint Colored Sealer

The application of AcquaTint Colored Sealer on a concrete basement floor is a simple process that requires proper surface preparation, application of the sealer, and proper maintenance to prolong the sealer’s durability. The steps are:

- Surface preparation: This includes cleaning the concrete surface, removing any existing coatings or sealers, and ensuring that the surface is dry and free of debris.

- Application of the sealer: AcquaTint Colored Sealer is applied to the concrete surface using a roller or sprayer. The sealer should be applied in thin, even coats, allowing each coat to dry completely before applying the next.

- Concrete floor wax application: After the sealer has dried completely, a concrete floor wax should be applied to the surface to provide an additional layer of protection and to prolong the sealer’s durability.

For a comprehensive and detailed guide on how to stain your concrete basement floor using colored sealer, refer to our guide “Colored Sealer Application for Your Basement Floor: A Step-by-Step Guide.” It provides clear instructions and helpful tips to ensure a successful and professional-looking outcome.

Step 6 – Select and Apply Concrete Sealer

After the stain has been applied, it’s important to apply a sealant to protect the surface and enhance the final look. For staining basement projects where smell and ventilation are going to be your biggest concerns, we generally recommend water-based sealers. They are nearly odorless, and will be safe to apply if your family or animals are in the home. It is important to choose a sealant that is compatible with the type of stain you have used and to follow the manufacturer’s instructions for application.

Step 7 - Apply Concrete Floor Wax (Optional)

For added protection and shine, you may choose to apply a concrete floor wax on top of the sealant. This will provide an extra layer of protection and make it easier to clean and maintain the floor in the future. Be sure to choose a wax that is compatible with the type of sealant you have used and to follow the manufacturer’s instructions for application.

In conclusion, staining your concrete basement floor is a great way to add color, character, and beauty to your space. With a little bit of preparation, the right type of stain, and proper application, you can achieve a professional-looking finish that will last for years to come.