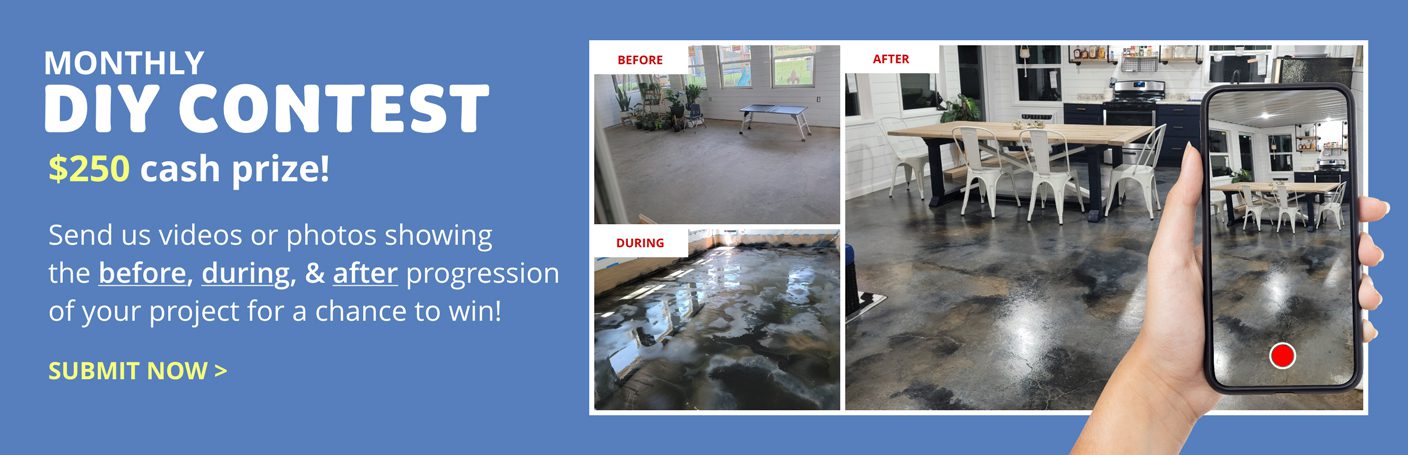

Before and After Photos of Charcoal and Gray Interior Concrete Staining

Forget what you heard about gray being drab and dull! This neutral color is perfect for bringing balance to any concrete surface you choose. Discover all that you can do with our gray concrete stain customer photos.

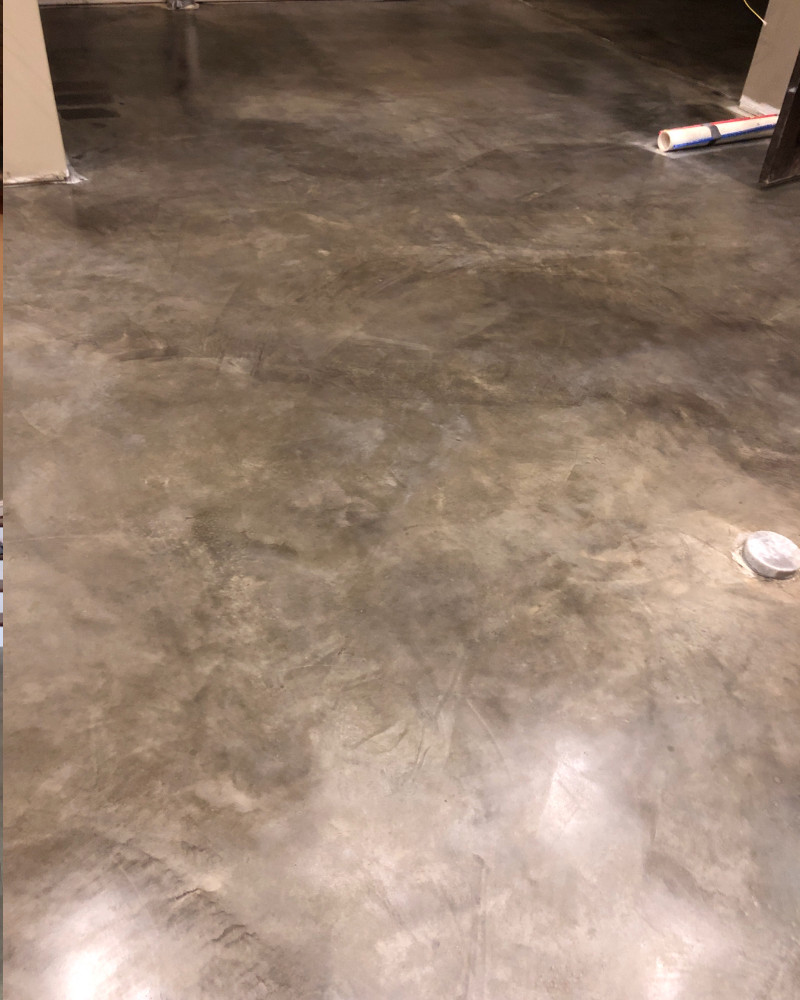

It’s Like a Brand New Basement

Industrial Look Kitchen Floor

This concrete floor was done with a mottled technique in four different shades of gray concrete dye. The whole industrial look comes together with the help of those lights and stools!

Simple Sunroom Makeover With Concrete Dye

Say ‘goodbye’ to that dull concrete floor like our DC customer did! With the help of Vibrance concrete dye, they transformed their sunroom into a stylish space. Learn how to do the same to your space with our how to guide!

Vibrance Dye Complete Makeover

-

- Project Completed In: 5 day(s)

- Estimate of Square Footage: 1600 sq. ft.

- Project Description:

Headache!!! I had an extremely unlevel floor. I had to grind down some areas 1 inch (about 400 sqft) and had to raise 300sqft 1 inch to get things overall with 1/2″. Then I had to pour 180 bags of the floor leveler and of course I was 16 bags short. This meant I was left with a cold joint for the final finish which I tried to accentuate and create a vein out of. Then I had to grind the surface to a 200 grit and blend the cold joint. Finally it was time to stain and stormy gray, white, and charcoal created one beautiful stained floor. This was a bit of an unorthodox project but I’m happy with it.I have more pictures also.I also plan to add a couple coats of direct colors floor wax when it arrives. I think that’ll really blend things out. I’ll know soon… - Personal Tips:

If possible to test your stain application and top coating method exactly as you plan to before hand, do it. My project turned out great from a stain aspect but the epoxy primer and urethane was only ok and I could have made that better but it’s alright for a first timer.Also, with the vibrance dye, don’t be dumb like me and step in it right after you spray it. I didn’t enjoy working those prints out.Finally, I may have applied too much stain but I found when applying my finish some dye would come up especially when brushing the edges. If possible, roll the edges when cutting in. - Direct Colors Products Used:

Stormy gray, white, and charcoal - Other Products Used:

VSEAL epoxy primer and urethane (3015 and 3321) industra-coat.

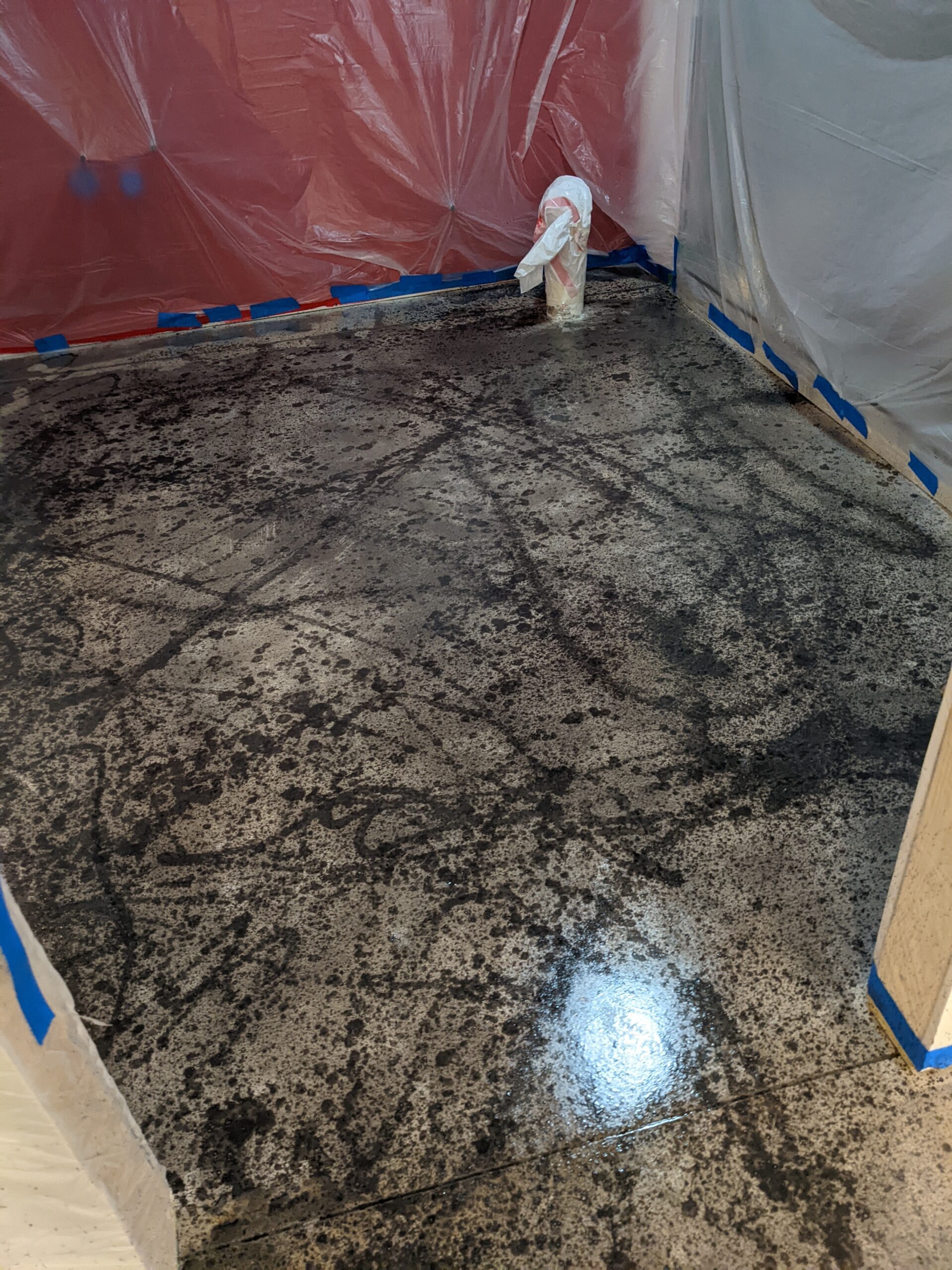

Graffiti Art

Our DC customer is a professional artist, but this was their first time dealing with concrete stain and a large-scale project. When their stain sprayer wasn’t working quite as intended, they improvised – creating random graffiti-like splashes of charcoal. What a unique look!

- Project Completed In: 6 day(s)

- Estimate of Square Footage: 1800 sq. ft.

- Project Description:

I have an unfinished 1800sf basement. I wanted to keep the integrity and durability of the concrete floors.

The floors had been grinded before any work had started.

First was cleaning up drywall dust, mud and paint off floors. Some was scraped off and then washed with diluted pine sol and water and finally just with plain water. This took about 6 hours everytime, constantly dumping the dirtied water.

I am a professional artist but this was my first time with concrete stain and such a huge scale.

The sprayer I used spit and dripped out the paint so I had to change my original plan to random graffiti-like splashes of the charcoal color. Spraying the initial design took 4-5 hours and 2/3 of the 5 gal charcoal. I let that dry 24 hours before starting 2nd coat of lighter gray.

I used a 3/8″ 9″ roller to apply lighter gray over splashed charcoal. Because I was creating a mottled, random look, it was impossible to roll on in one direction as is suggested. It created lines I didn’t like. Rather, I went heavy in some areas and left the lightness of one coat in other areas, always careful to cover bare concrete. The lighter gray helped to soften the contrast of the lighter areas and the charcoal. This effect took about 2 of the 5 gal. container. Because of the sheer size of the floor, it took 6-7 hours.

After waiting 24 hours, I began 1st coat of wax with a 9″ Shurcoat paint pad. It was very had to tell where I covered because of the mottled nature of the colors. After 4-5 hrs. I applied a 2nd coat of wax, noticing some areas had a higher sheen to them. I wasn’t sure why this was happening but it helped create depth on the floor.

The next morning, I applied a 3rd coat of wax, a bit heavier to achieve the desired high gloss look. That was left to cure a full 24 hrs. I used 4 of the 5 gals. to do all 3 coats of wax. Each coat took about 4-5 hours to complete.

Personal Tips:

Aquatint settles very quickly and must be constantly stirred.

Enjoy the way the stain works when using more than one color.

Make sure you have very good lighting to apply both stain and wax.

Direct Colors Products Used:

-

- 5 gal Aquatint Charcoal

- 5 gal Aquatint Gray

- 5 gal high gloss wax

Other Products Used:

-

- 3/8″- 9″ roller

- 9″ Shurcoat paint pad -3, one for each coat of wax

- 2 gal Chapin premier sprayer

Accentuating Concrete Swirls

There’s nothing like completing a tough DIY project yourself! This customer felt that adding sealer to their concrete was a “rewarding project”. They knew they wanted a concrete stain that was transparent yet durable, and AcquaTint was the product that ticked all the boxes.

- Project Completed In: 3 day(s)

- Estimate of Square Footage: 1500 sq. ft.

- Project Description:

We are finally all moved in and getting around to showing you all our results! We knew we loved and wanted to accentuate the power trial swirls and marbling effect. We spent hours and many test products under where our cabinets would be, but look no further direct colors has the perfect product. We ended up choosing the tinted sealer. We knew we wanted a very transparent but durable stain.

Essentially all we did was thoroughly clean the dust and construction grime off the floors with degreasing soap and let that dry a few hours. We then came back and cleaned our floors THREE more times with the direct colors degreaser, two of which were rinses. This alone took a full day for 1500sqft. Once this dried we were ready to stain. We tried many methods (sprayers, sponges, rags) and the best we came across for a super transparent look was a 18” floor squeegee! It worked awesome. Like any paint project it is all in the prep work and the actual staining process was over before we knew it, maybe 1.5hrs. After this we let it dry for a day and covered in plastic to finish construction. Once we were ready to move in we washed it again, then immediately waxed the entire floor(last picture) as you can see the floor is almost a living feature of the house as it changes color and hue based on lighting effects. Overall this was a rewarding project that we are happy to have done ourselves! Have fun!

Personal Tips:

Clean clean clean, have all supplies organized and clean up (acetone, in our case) ready. Have an extra applicator (spray gun squeegee etc.) on hand in case yours fails/breaks

Direct Colors Products Used:

-

- 1 qt ProClean Degreaser

- 1 gal Aquatint Charcoal

- 1 gal Satin Acrylic Sealer

- 1 gal Satin Floor Wax

Coffee N’ Crafts

The method used to apply tinted concrete sealer depends on the look you want to achieve. For Coffee N’ Crafts, a marbled, varied color was the mission for Brad Carlisle from William B. Carlisle Design. The best part about this renovation? They performed a complete space upgrade without having to rip up the concrete floor!

Silver Simplicity

This commercial space really looks spiffy after applying some silver colored concrete sealer. And hey, if you like what you see here, check out our handy how to guide for applying tinted sealer!

Tinted Sealer for the Win

This commercial space used the same Silver Gray AcquaTint stain over a colored concrete floor. Check out our handy how to guide for applying tinted sealer!

Keep the Grandkids Out When You DIY!

Our Direct Colors customer offered some valuable advice when working on your tinted sealer project: make sure you cover walls and doors! And keep grandkids out! Yes, these things are always important to remember! They used AquaTint and solvent based sealer for the concrete floors in their new home.

Project Info:

- Project Completed In: 5 day(s)

- Estimate of Square Footage: 1600 sq. ft.

- Project Description:

We are building a barn house. It is semi finished. The walls are painted shiplap. - Personal Tips:

I was so afraid of messing up with the sprayer that my first coat was way too light. I applied 2 more coats and it looked great. I believe the aquatint is very forgiving when sprayed on. I followed up with 2 coats of the solvent based satin sealer. Make sure you can open up plenty of windows because this stuff STINKS! Even though my concrete is not perfect I love my floors.

Make sure you cover walls and doors! And keep grandkids out!

Direct Colors Tip: When sealing indoors, we recommend our water-based AcquaSeal sealers. They are low VOC, so you will not stink up your house.

- Direct Colors Products Used:

AcquaTint in light charcoal. Acrylic sealer solvent based in satin.

Other Products Used:

No additional products except lots of elbow grease!

Fun with Texture

While tinted concrete sealer won’t cover imperfections, it allows you to give your concrete floor character! That’s what this customer did. We think that the tinted sealer complements their textured floor so well.

Project Info:

- Project Completed In: 3 day(s)

- Estimate of Square Footage: 250 sq. ft.

- Project Description:

We’re redoing our main bathroom and want stained textured concrete floors. The area includes the hallway, closets, bathroom area and water closet.We started by laying the concrete and then sanding. Then we used charcoal aquatint, applied using a roller. We followed the instructions completely and the application went very well. - Personal Tips:

The color deposits at the bottom of the bottle so the first few coats are somewhat lighter. We left about 10% tiny in the first bottle and mixed it in when starting the second bottle. It helped create a more even second application. - Direct Colors Products Used:

Aquatint charcoal and wax sealer.

Other Products Used:

Direct colors applied onto Henry feather finish concrete mix.

No More Carpets!

After this DC customer’s basement flooded for the second time, they decided no more carpet! While coloring their concrete basement floor with tinted sealer was a challenging project to complete, they felt that the right products made it doable.

Project Info:

- Project Completed In: 21 day(s)

- Estimate of Square Footage: 1000 sq. ft.

- Project Description:

After my basement flooded for the second time I decided no more carpet. This was a challenging project but with the right products it can be done.

1.) first I rented a concrete grinder for the day and etched the floor. My basement was sealed when my house was built so it was a necessary step.

2.) I mopped the floor two times to remove any dust or residue.

3.) I applied two coats of AcquaTint™ Silver Gray Water Based Colored Sealer, waiting 24 hours in between each coat. I rolled the stain on with roller purchased through direct colors. I would strongly recommend that because it is a high quality roller.

4.) I used a dollar store sponge mop to apply three layers of direct colors Residential Concrete Floor Wax, waiting three hours in between each layer.

5.) I waited 24 hours before placing furniture on the floor. - Personal Tips:

Be careful when rolling on stain not to overlap because it can dry with lines. - Direct Colors Products Used: 5 Gal. Satin AcquaTint™ Silver Gray Water Based Colored Sealer

Concrete Floor Wax - Other Products Used:

Concrete grinder

Revamping A Basement Into A Comfortable Living Area

We were determined to transform our 100-year-old basement into a livable space, but we were discouraged by the high cost of hiring professionals to stain the concrete floor. So, we decided to take on the project ourselves with the help of Direct Colors.

The first step was to remove all the old stains, spray paint, and overspray from the floor. We rented a concrete grinder and used a handheld angle grinder with a surface grinding tool to get into the hard-to-reach areas. We also patched a few small hairline cracks with a basic cement mix from the hardware store.

Next, we cleaned up all the dust and mopped the floor three times – once with soapy water and twice with clean water. Once the floor was dry, we taped off the walls with plastic and sprayed a coat of solvent-based satin sealer. We waited about 12 hours for the sealer to dry before applying two coats of White Vibrance Dye, with the recommended drying time between each coat. We followed the same process with Stormy Grey Vibrance Dye and then added some dimension to the floor with Charcoal Grey Vibrance Dye. After the final coat of dye dried, we applied two coats of solvent-based satin sealer, waiting 12 hours between each coat.

We were thrilled with the final result and couldn’t have done it without the guidance and products from Direct Colors. Our biggest issue was with sprayer malfunctions, but don’t let that deter you! With a little prep work and some patience, you can achieve beautiful, professional-looking results on your own. Some of our personal tips include testing your sprayer before starting, not skimping on prep work, and having a bucket and rag on hand to fix any drips or clogs. We also recommend waiting about an hour and a half for the dye to be ready before spraying and making sure to follow the recommended drying times.

Check out more detailed information about this concrete dye project.

Staining Concrete with Water-Based Tinted Sealer

If you’re looking to add a pop of color to your concrete flooring, water-based tinted sealer is a great option. Not only does it provide a beautiful finish, but it’s also easy to apply and maintain.

For more detailed information about this project, check out this link.

Unfinished Basement Gets a Mottled, Graffiti-Inspired Makeover with Aquatint Charcoal and Gray

In this project, the customer transformed an unfinished 1800 sq ft basement floor using Aquatint Charcoal and Gray. The floors had previously been grinded and the customer spent 6 days on the project, including cleaning up drywall dust, mud, and paint from the surface. The customer used a sprayer to apply the initial design, which took 4-5 hours and used 2/3 of the 5 gallon container of charcoal. After letting the initial coat dry for 24 hours, the customer used a roller to apply a lighter gray color over the splashed charcoal, creating a mottled, random look. This took 6-7 hours and used 2 of the 5 gallon container.

After waiting another 24 hours, the customer applied three coats of wax using a paint pad, achieving a high gloss finish. Each coat took 4-5 hours to complete and used 4 of the 5 gallon container. The customer recommends stirring Aquatint constantly to prevent it from settling, enjoying the way the stain works when using multiple colors, and making sure to have good lighting when applying both the stain and wax.

For more detailed information about this project, check out this link.

ColorWave® Stain: Stunning DIY Concrete Transformations

Explore our gallery of before-and-after photos featuring DIY concrete staining projects. From living rooms to patios, see how ColorWave® Stain makes a difference.

By Justin Richardson

Modern Basement with Molasses-Stained Concrete Floor

This project transformed a basement space with a smooth concrete floor stained using Molasses ColorWave®. The rich brown tones add warmth and sophistication, enhancing the bar, dining, and living areas with a polished, contemporary look.

Project Info:

-

- Project Completed In: 5 day(s)

- Estimate of Square Footage: 1500 sq. ft.

- Project Description:

We wanted to finish our basement with a unique style. So my wife and I decided to utilize the new concrete as the finished floor using a stain and sealer. - Personal Tips:

The cleaning process is the most tedious and time consuming, but it is the most important part. Make sure you are using compatible products for removing stains or paint from the floor to avoid any potential issues between DC products and cleaners. Lastly, follow the directions and do not cut corners. - Direct Colors Products Used:

5 Gal. Molasses ColorWave® & AcquaSeal™ Satin Kit

1 Gal. AcquaSeal™ Satin

5 Gal. ProWax Polish™ Satin - Other Products Used:

Simple green cleaner, floor scrubber, and a shop vac.

Please be aware that each photo in this gallery showcases projects accomplished with our ColorWave® Water-based Stain and is provided by actual customers, serving as a source of inspiration. However, since ColorWave® is semi-transparent, the final appearance of your project will be influenced by the initial color and condition of your concrete surface, and thus, your final results might vary. For the best results, we strongly recommend performing a small test on your specific surface before applying the stain to the entire project to ensure the final look aligns with your expectations.

Tri-Room Remodel with ColorWave® Stain

This project highlights a transformative remodel of a kitchen, family, and laundry room, where everything was stripped down to the concrete and rejuvenated using ColorWave® Stain. Despite some challenges with the gloss application and a slight texture in the finish due to overgrinding, the result is a revitalized space with a pleasing new aesthetic.

Tip: Apply the stains in a wet-on-wet technique, similar to acid staining, and used multiple layers to achieve the desired effect.

Project Info:

- Project Completed In: 7 day(s)

- Estimate of Square Footage: 500 sq. ft.

- Project Description:

Complete Kitchen, Family and Laundry Room remodel taking the rooms down to the studs including 2 layers of flooring to reveal the concrete. - Personal Tips:

I originally was drawn to the acid stain floors but chose ColorWave for the convenience but applied it somewhat like an acid stain with the wet on wet multiple colors. I started out with a white only (which I would skip were I to do it again). I did 3 layers of color, but two would have have worked well. I especially love the Silver which in certainly light a baby blue and reacts with the Iron Gray to be similar to a dark Navy.I used a first coat sealer of the EasySeal Satin and then topped it off with the EasySeal Gloss. The satin coverage was perfect, but the Gloss seemed to be soaking in too much in some areas and glossing better in others. I ended up putting 3 thin coats of the gloss for the best coverage. It is not fully glassy as I had hoped but has a slight texture which I believe is due to some overgrinding in areas. I finished with 2 coats of High Gloss Floor Wax. Due to the fumes in EasySeal Solvent Sealer, I would choose the water based sealer even though it is not as good for “re-sealing.” - Direct Colors Products Used:

ColorWave® Stain Trial Kit (Navy, Rust & Stone)

ColorWave® Stain Trial Kit (Black, Blue, Steel)

Patch-Rx™ Concrete Repair: Base Gray: 2.5 lbs

Patch-Rx™ Concrete Repair: Base White: 2.5 lbs

1 Gal. Silver ColorWave® Stain

3 x 1 Gal. White ColorWave® Stain

2 x 1 Gal. Stone ColorWave® Stain

1 Qt. Iron ColorWave® Stain

3 x 1 Gal. EasySeal™ Gloss

1 Gal. ProWax Polish™ Gloss - Other Products Used:

Angle Grinder with Diamond Blade, Rotating Sander, Simple Green Degreaser, Wet Dry Shop Vacuum.

From Basement Mess to Marble Elegance

This project transformed a mastic-covered basement into a marbled masterpiece using White and Steel Gray ColorWave® stains. Despite initial tile ghosting, the application of sealer revealed a floor resembling a magnified marble slab, adding an extraordinary touch to an ordinary basement.

Project Info:

- Project Completed In: 7 day(s)

- Estimate of Square Footage: 420 sq. ft.

- Project Description:

I had a basement that was about 3/4 mastic that flooded about 5 years ago. When it flooded all of the 1970’s tile that was under the carpet lost its adhesion and came away. I was left with all the black asbestos mastic and a mess. Luckily I had already used Direct Colors for my countertops so I figured if there was one place that could solve my ugly basement this was the place. - Personal Tips:

BE PATIENT it is worth doing right and letting the product dry and/or cure for the correct time.Also, I had a lot better luck using one of the twist mops when applying the polish and just going over it lightly - Direct Colors Products Used:

1 Gal. Steel DIY ColorWave® & AcquaSeal™ Gloss Kit

2 x 1 Gal. White ColorWave® & AcquaSeal™ Gloss Kit

1 Gal. White ColorWave® Stain

1 Gal. ProWax Polish™ Gloss

1 Gal. CitrusEtch™ Concrete Etcher

1 Qt. ProClean Neutralizer™ Concentrate

1 Qt. ProClean Degreaser™ Concentrate

1 Gal. Bean-E-Doo Mastic Remover - Other Products Used:

Libman floor brush

Twist mops

Floor scraper

Spyder scraper blade attachment for saw all

DIY Marbled Concrete Floors Using the Puddling Method

Breath new life into your space using ColorWave’s Black, Stone Gray, and Iron Gray hues.

Project Info:

- Project Completed In: 3 day(s)

- Estimate of Square Footage: 430 sq. ft.

- Project Description:

We used Colorwave Black, Stone Gray and Iron gray, used the “puddling method” and finished it off with an acrylic water based high gloss sealer. We also put 2 coats of wax afterwards. - Direct Colors Products Used:

1 Gal. Black ColorWave® Stain

1 Gal. Iron ColorWave® Stain

1 Gal. Stone ColorWave® Stain

3 x 1 Gal. AcquaSeal™ Gloss

1 Gal. ProWax Polish™ Satin - Other Products Used:

Wet Dry Shop Vacuum.

Industrial Basement Transformation: Crafting a Modern Home Office

Explore the transformation of an unfinished basement into a sleek, industrial home office. A homeowner overcame paint overspray and etching marks by using stain samples and a buffing technique to achieve a distinct stone-like look. Dive into this inspiring project to learn how to craft your own floor makeover.

Project Info:

- Project Completed In: 4 day(s)

- Estimate of Square Footage: 210 sq. ft.

- Project Description:

Our project is to make our basement into some usable bonus space. We aren’t completely finishing out the space but going for a polished industrial type of look. This space will be a future work from home office space. - Personal Tips:

We had a lot of paint overspray and learned that vinegar works great to pull that up and on stubborn areas my steam shot cleaner worked great. Don’t skimp on the prep, it was so much work but definitely necessary.We etched our floors and after the first coat of stain, we could see all of our scrub brush strokes from etching, it looks really bad. When the brush marks didn’t dry away we were left to problem-solve. We took out black and silver samples and tried to hide the worst areas. We left that to dry a bit and it didn’t look quite right so we actually took our bissell spinwave mop and swirled/buffed the stain. This worked great! It hid the etching marks and made a really nice stone type of look with the three colors. It was a rollar coaster but I love how it turned out. - Direct Colors Products Used:

ColorWave® Stain Trial Kit ( Black, Silver & Stone)

2 x 1 Gal. Steel ColorWave® Stain AcquaSeal™ Gloss Kit - Other Products Used:

Rust-Oleum Clean & Etch & ZEP Wet-Look Floor Polish

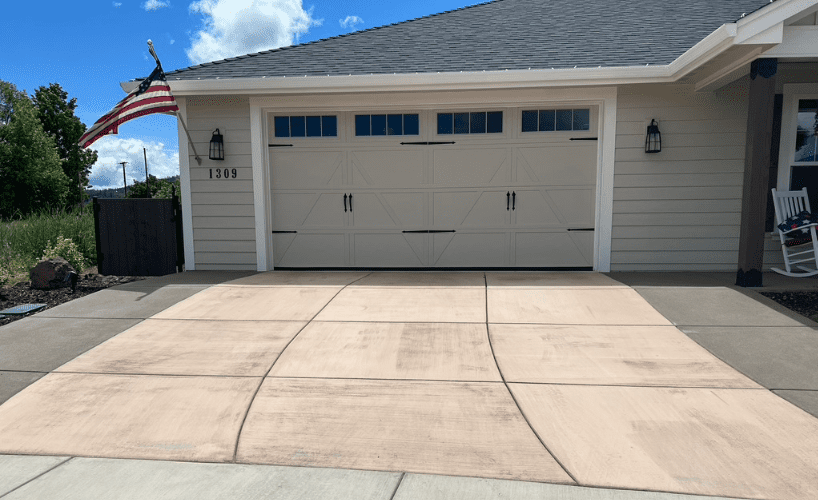

Fixing a Pink Concrete Driveway

This customer wanted a rich brown concrete driveway to match their home’s wood accents but ended up with a light peach color. After finding Direct Colors, they used ColorWave® stain to achieve the perfect shade.

Project Info:

-

- Project Completed In: 3 day(s)

- Estimate of Square Footage: 336 sq. ft.

- Project Description:

We wanted colored concrete for the middle section of our driveway. We selected a color from the concrete company, a color that was supposed to match the stained wood accents on the front of the house. Once is was all dry, the color was more light peach colored than the rich brown we were hoping for. Fast forward a few years and I found Direct Colors online. They seemed to have the answer to our problem. After carefully trying some samples, I ordered a whole batch of stain, antiquing, and sealer. The results are beautiful and exactly what we wanted. And I have plenty left over to fix our patio in the backyard. Thanks Direct Colors! - Personal Tips:

Tip #1– after the color don’t use the spiked candles on you shoes. I found, even walking very carefully, it left marks in the color. Since the color was dry and I was rolling the sealer, I simply wore an old pair of socks.

- Direct Colors Products Used:

3 x 1 Gal. Molasses ColorWave® Stain EasySeal™ Satin Kit

3 x 1 Gal. Aztec Brown Antiquing™ Stain

Achieving a Natural Stone Effect with ColorWave® White and Blue Stain

This project involved transforming the flooring of an entire home built on a slab on grade . The goal was to make the concrete floors resemble stone rather than plain concrete. White ColorWave® was applied throughout the home using a dry mop and hand-held pump sprayer, with blue added to the laundry and walk-in shower.

Project Info:

- Project Completed In: 3 day(s)

- Estimate of Square Footage: 2300 sq. ft.

- Project Description:

We have a slab on grade home that we chose to use those concrete floors as our flooring throughout the entire home. We wanted to add some color to them to make it look more like stone than just a plain concrete floor. We applied ColorWave white to the entire floor with a dry mop. We applied the white stain color using a hand held pump sprayer to the entire floor and then dry mopped it. We also added blue to the laundry and walk in shower. We power washed and wet vac on Friday. Vacuumed any leftover debris on Saturday morning applied the white and blue colors Saturday morning and put the first coat of sealer on Saturday afternoon. The second coat of high-gloss sealer went on Sunday afternoon. - Personal Tips:

We used the dry mop because we wanted more of a cloudy look than a sprayed on paint look. When rubbing the color in using the dry mop use circular motions rather than side to side. - Direct Colors Products Used:

ColorWave® Stain Trial Kit

5 Gal. White ColorWave® & EasySeal™ Gloss Kit

1 Gal. White ColorWave® Stain

1 Qt. Blue ColorWave® Stain

5 Gal. ProWax Polish™ Gloss - Other Products Used:

Wet Dry Shop Vacuum.

Mottled Makeover for a Pre-K Space

This Pre-K space was transformed with a mottled effect using ColorWave® Stain in Molasses and Mahogany. Two coats of EasySeal™ and a finish of ProWax Polish™ resulted in a lively and engaging environment for little learners.

Project Info:

- Project Completed In: 5 day(s)

- Estimate of Square Footage: 350 sq. ft.

- Project Description:

After concrete prep everything was easy the stain, sealer, and polish. Love the look and the finished product. - Personal Tip: Never put paint or adhesive on concrete. It’s hard to get off.

- Direct Colors Products Used:

1 Gal. Mahogany DIY ColorWave® & EasySeal™ Gloss Kit

1 Gal. Molasses ColorWave® & EasySeal™ Gloss Kit

5 Gal. ProWax Polish™ Gloss - Other Products Used:

Finish sander ( rented)

And a lot of mop water.

Revitalized Stamped Patio with ColorWave® Stain

After using the ColorWave Kit, this once-faded patio is now beautifully restored with rich Molasses and Mahogany tones, creating an inviting outdoor space.

Project Info:

- Project Completed In: 3 day(s)

- Estimate of Square Footage: 500 sq. ft.

- Project Description:

I have a ten year old faded patio that was originally colored concrete that was stamped and stained. Over the years I’ve tried applying sealer to make the faded color pop but was not successful. I found Direct Color and used the Colorwave Kit to clean, etch, stain and seal my patio back to its original but even better beautiful artsy style and finish! - Personal Tip: After I sprayed on the two Colorwave stains Mahogany and Molasses I then used an old broom to blend and smear them into the concrete stamp groves. I sprayed the sealer on and then used a paint roller on an extension pole to evenly spread it out.

- Direct Colors Products Used:

1 Gal. Mahogany DIY ColorWave® & AcquaSeal™ Satin Kit

1 Gal. Molasses ColorWave® & AcquaSeal™ Satin Kit

Custom Concrete Countertop by @cretewooddesigns

A custom concrete countertop created by @cretewooddesigns. The project involved working in layers and using water to blend colors, allowing for easy manipulation of the finish before sealing, resulting in a unique and much-appreciated final product.

Project Info:

- Project Completed In: 4 day(s)

- Estimate of Square Footage: 23 sq. ft.

- Project Description:

This was a custom concrete countertop project for our friends. They absolutely love it! ❤️ - Personal Tips:

Work in layers until you get the look you want. The product runs off easily before being sealed, so it’s easily manipulated to the finish you are wanting. Also, using water to help the colors come together well results in a unique look. - Direct Colors Products Used:

ColorWave® Stain Trial Kit (Iron, Molasses & Rust)

ColorWave® Stain Trial Kit (White, Steel & Stone)

1 Gal. Iron ColorWave® Stain - Other Products Used:

Trinic topical sealer

DIY Concrete Sunroom Makeover: Adding Character with ColorWave Gold Stain

If you’re looking to add some character to your outdoor space, a concrete patio makeover may be just the thing you need! That’s exactly what one DIYer did with their small 8×20 sunroom patio, and the result is stunning.

Project Info:

- Project Completed In: 5 day(s)

- Estimate of Square Footage: 160 sq. ft.

- Direct Colors Products Used:

1 Gal. Gold DIY ColorWave® & EasySeal™ Satin Kit

DIY Driveway Transformation with Water-Based Concrete Stain

Are you tired of looking at a faded and dull concrete driveway? With a little bit of elbow grease and the right materials, you can transform it into a beautiful, refreshed space. That’s exactly what one DIYer did, and the results are excellent.

DIY Driveway Paver Re-Staining: Water Based Concrete Stains Before & After

Are your concrete pavers looking faded and dull? Give them a fresh new look with a DIY re-staining project! That’s exactly what one DIYer did, and the results are impressive.

Staining Heated Concrete Floors

If you live in an area with harsh winter weather, a heated concrete driveway might be the perfect solution to keep your surface clear of ice and snow. With ColorWave stains, you can safely stain heated concrete floors without compromising the functionality of the heating system. These stains work well on both interior and exterior heated concrete, as they color the surface without interfering with the heating elements embedded within the concrete.

Project Info:

- Project Completed In: 15 day(s)

- Estimate of Square Footage: 360 sq. ft.

- Project Description:

New heated driveway approach - Direct Colors Products Used:

1 Gal. Almond ColorWave® Stain

1 Gal. Amber ColorWave® Stain

1 Gal. Olive ColorWave® Stain

2 x 1 Gal. AcquaSeal™ Gloss

Garage Floor Makeover

Project Info:

- Project Completed In: 5 day(s)

- Estimate of Square Footage: 500 sq. ft.

- Project Description:

My garage was unsightly; The previous owner applied some kind of coating and sealant that was coming up. I rented a concrete grinder to remove the coating. This took 2 days and was the hardest part of the project.On day 3 I applied 3 coats of ColorWave Amber. This was easy and only took 15 minutes per coat using a pump sprayer.On Day 4 I applied the first coat of EasySeal gloss. The directions say this can be applied using a pump sprayer, but it is too thick. I had to stop my project to go buy a roller and tray. I was worried the roller would leave streaks, but there are only a few and they are not very noticeable unless you are looking for them.I left the garage door open overnight because the VOC’s are no joke! I even turned off the AC because it was pulling air in from the garage and stinking up my house. I am not complaining though because I know this product will last!Day 5 I applied the second coat of sealer without any issues.The real test was 3 days later when I put the cars back in the garage. I was worried the coating would peel up and leave hot tire marks, but it didn’t!I would totally recommend these products for the DIY’er, I saved thousands of dollars from the quotes I received.

- Direct Colors Products Used:

3 x 1 Gal. Amber ColorWave® Stain & EasySeal™ Satin Kit - Other Products Used:

Blastrac concrete grinder./li>

A Tribute to Prince

Stylish Entryway Floor

Outdoor Kitchen with Stained Countertop

Molasses-Stained Patio

Vibrant Mahogany and Molasses Floor

Stone, Steel and White ColorWave®

Black and Steel Gray Stained Hallway

Steel Gray ColorWave®

Steel ColorWave® on Stamped Concrete

Black & Silver ColorWave®

ColorWave® Stained Flagstone Patio

Black & Silver ColorWave®

Molasses and Steel Gray

Sunset-Stained Outdoor Countertop

Cozy covered patio with Olive ColorWave®

Stained Concrete Compass Design

Stained Fire Pit Patio